Silicon carbide devices have broad application scenarios. Due to its high thermal conductivity, high breakdown electric field strength, and high current density, semiconductor devices based on silicon carbide materials can be applied in multiple industrial fields such as automobiles, charging equipment, portable power supplies, communication equipment, robotic arms, and aircraft. The scope of its application is also constantly being popularized and deepened, making it a very promising and valuable material.

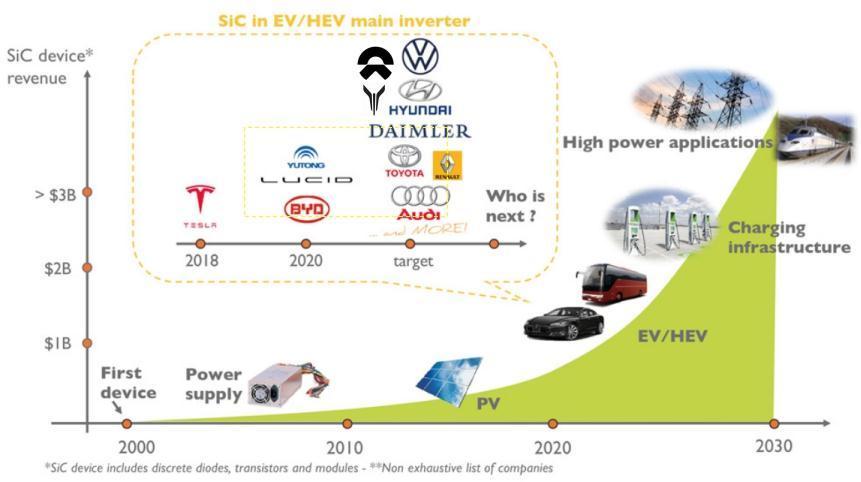

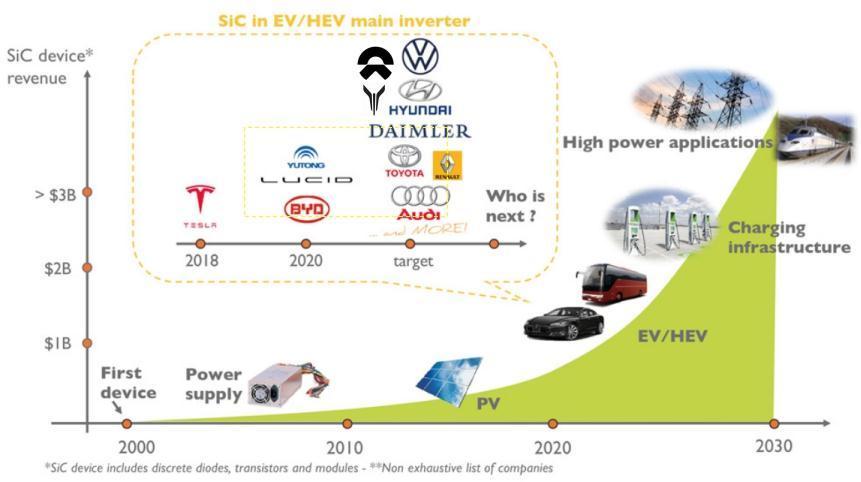

Application schedule and situation of silicon carbide in various fields

The field of new energy vehicles will bring huge growth to silicon carbide (SiC) power devices. In new energy vehicles, silicon carbide has various advantages in power applications and can work in high temperature, high pressure and other working environments. At the same time, it has higher energy conversion efficiency and is considered a power device material that exceeds the limit of silicon. Silicon carbide devices are mainly used in new energy vehicle driver inverters, OBCs (on-board chargers), DC-DC on-board power converters, and high-power DCDC charging equipment. With the successive launch of 800V voltage platforms by major car companies, in order to meet the needs of high current and high voltage, the main drive inverter of the motor controller will inevitably be replaced with SiC-MOS from silicon based IGBT, bringing huge growth space.

Advantages of Silicon Carbide (SiC) in Electric Vehicle Applications

According to Yole‘s statistics, as of 2022, BYD‘s Han EV (250.880, 1.60, 0.64%) and Hyundai‘s IONIQ 5 have achieved good sales by providing fast charging capabilities. More OEM companies such as NIO and Xiaopeng have also introduced silicon carbide devices to the market in 2022.

Silicon carbide (SiC) power devices can improve the conversion efficiency of photovoltaic inverters and reduce energy loss. In terms of photovoltaic power generation, traditional inverters based on silicon based devices currently account for about 10% of the system‘s cost, but are one of the main sources of energy loss in the system. The photovoltaic inverter using silicon carbide (SiC) MOS as the basic material can increase the conversion efficiency from 96% to over 99%, reduce energy loss by over 50%, and increase the equipment cycle life by 50 times. This can reduce the system volume, increase power density, extend the device service life, and reduce production costs.http://www.ic-bom.com/